Transmissions

The Borg Warner/Tremec T56 transmission is very well engineered 6 speed that can be upgraded to perform better than the original engineers intended to. Most 6 speed owners want to upgrade to Stage I; Stage II; Level I; Level II, so on and so forth but most people don’t know the reason behind the upgrade.

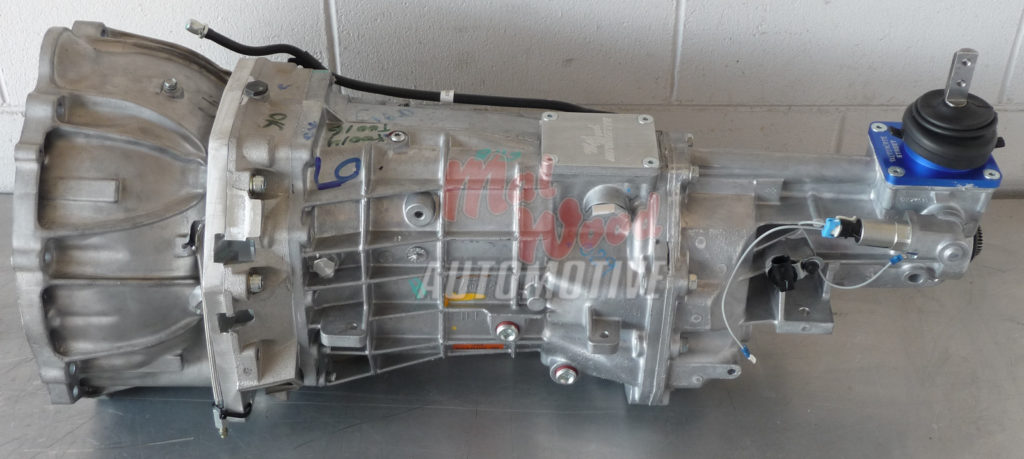

t56 transmission parts & rebuild kits. 2004r 350 3l30 700r4 4l60e 4l65e 4l70e 4l30e sm318 sm319 st300 jetaway saginaw etc transmission & bw1372 np207 np231 np233 np247 np249 transfer case tail housing bushing 1.630' o.d. Featuring a 700 lb.-ft. Maximum torque capacity, the T56 has an exterior case similar to the fourth-generation F-body transmission. The T56 also includes stronger, high-capacity gear sets, input shaft and output shaft used in the TREMEC TR6060. This version is to suit what would be considered the early GM t56 cars and include the gearboxes from: Vt – Vz Holden Commodore (T56 only). 4th gen Camaro/Firebird. There is also an aftermarket T56 transmission available through selected Chevy dealerships like Burt Chevrolet. This transmission was designed as a direct replacement six-speed for ’82-’92 Camaros.

In 1993 the GM F body (Camaro/Firebird) used the T56 and was offered in a 2.66 1st gear, a 2.97-1 1st gear, and in 1993-94 a 3.36 1st gear was available. The T56 continued to use the paper-lined synchro rings and employed a double cone 1st and 2nd gear synchronizer, while 3rd, 4th, 5th, and 6th remained single cone design.

OEM manufacturers build transmissions with objectives in mind but the bottom line is always the cost. In order to save on costs, they use parts that will be easy to produce and inexpensive to manufacture. For normal street use, these parts stand up quite well and last up to 100,000 miles or more.

When the T56 is out side of street environment, all of that changes. Here are some of the weak parts:

- The 3rd gear is the most commonly missed gear and when pushed hard into 3rd gear, the aluminum 3-4 shift fork can break. (symptom: no 3-4 gears)

- The stamped steel keys in the synchronizers often break into several pieces since it wasn’t built to handle the rigorous shifting. (symptom: stuck in gear and won’t come out)

- The transmission goes through heat cycles every time the vehicle is driven for any length of time but when driven aggressively, the heat can make the plastic shift fork pads brittle. The plastic fork pads often crack and fail. (symptoms: grinding, popping out of gear)

RKT Performance offers a basic upgrade package that replaces all the “weak links” in the T56 with the following parts:

- Billet synchronizer keys

- Steel 3-4 shift fork

- Bronze fork pads

With the above upgrades, the T56 will perform well under all aggressive shifting environments.

Click Here to View Photos of Failed Components

T56 Engine Gearbox

The one on the left has billet keys compared to the stamped keys on the right.

Borg Warner T56 Transmission Diagram

Close up of the billet key.

Close up of the stamped key.

Broken stamped steel keys; new stamped keys; damaged billet keys; new billet keys.

Close up of stock stamped steel keys.

Close up of billet keys. The billets keys on the left were damaged but did not fail.

Stamped steel 1-2 keys; Solid 1-2 keys.

Comparison between plastic fork pads and bronze fork pads.

This is the comparison between the aluminum 3-4 shift fork and the steel 3-4 shift fork.

This shot shows the broken aluminum fork “fingers”.

Another shot of the broken 3-4 shift fork compared to the steel fork.

Of all the misnomers we encounter in the automotive aftermarket, one of the most common stems from the confusion surrounding the TREMEC T-56 6-speed transmission and its Magnum 6-speed protégé. Granted, one could argue that the two models have more in common than not; however they are in fact completely different transmissions. If you are considering a TREMEC for your car, it’s important to know the differences in order to make sure you don’t waste money on the wrong transmission, or one that falls short of your performance objectives.

Background

Appreciating the differences between the Magnum and its T-56 predecessor starts with knowing the history of both transmissions. We’ll start in the late 1990s, when TREMEC was well on its way to becoming a household name among stick-shift enthusiasts, thanks to the growing popularity of our TKO transmission in the budding 5-speed muscle car conversion market. During this same period, following the acquisition of BorgWarner’s manual-transmission business in December 1996, TREMEC was successfully producing the T-56 for use in just about every rear-wheel-drive performance car being offered by the Big 3 automakers – and even a few outside of them.

As the hot rod restomod market continued to explode, the TKO – re-released in 2004 as the TKO-500 and TKO-600 – continued to lead the charge, particularly among those with early engine combinations. The T-56, however, had garnered appeal among enthusiasts who embraced the more recent GM LS and Ford Modular engines. At the same time, salvage yards had become flush with the factory offerings, making LS1/T-56 conversions from wrecked Camaros and Trans Ams in particular a very popular swap.

Much like today though, the factory T-56s were tailored specifically to the OE applications from which they came, meaning that gear ratios were sometimes undesirable and shifter locations were often less than ideal for an early muscle car – forcing the use of awkward-looking custom consoles. Last but not least, speedometer provisions on the transmission were typically incompatible with classic applications. In short, these swaps left a lot to be desired. Add to that, the limited torque capacity of some factory units, as well as, the fact that many had been severely abused before ending up in a boneyard, and the need for an aftermarket solution was clear.

Fortunately, the timing was right for a response from TREMEC. Prompted by ever-increasing torque demands and the desire for improved shift quality from our OE customers, in 2004, we began working on a replacement for the T-56. Debuting in the Ford Shelby GT500 for model year 2007, the new TR-6060 6-speed quickly became the go-to performance transmission of the industry. By 2008, it had superseded the T-56 in pretty much all OE performance applications.

Addressing the need for a more flexible solution for the custom car market, our engineers also went to work on an aftermarket-only version of the TR-6060. Working with input from the TREMEC marketing team, they took swap-friendly features from the TKO and modeled the input side of the trans after the popular T-56 applications in order to leverage existing market support. GM versions of the Magnum were modeled after 1998-2002 F-bodies and Ford versions after the 2003-2004 Terminator Cobra. In 2009, TREMEC released the new T-56 Magnum. Using T-56 in the name was intended to let customers know the trans was not some brand-new, unproven design; the name Magnum signified that this new unit was indeed something special – unique from all T-56 transmissions that came before it.

T56 Gearbox For Sale Nz

Unfortunately, the naming strategy confused large portions of the market that didn’t know the Magnum was actually more TR-6060 than it was T-56, and that there was little in common application-wise with either OE model. In addition, the T-56 name itself had so much goodwill in the market that many enthusiasts chose to ignore the Magnum part altogether and continued to use the T-56 moniker instead, rather than the other way around.

Now that you know some of the history leading up to the Magnum, and are clear that it is not a T-56, let us take a deeper look at what separates the TREMEC Magnum and its TR-6060 sibling from the T-56 that came before them.

The TREMEC Magnum and TR-6060 utilize 2-piece speed gears. The clutching ring and gear are forged and machined separately. They are then interference-fit and laser-welded together. This type of construction does away with the previously wasted space in the T-56 design. Combined with the new synchro design, the TREMEC engineers could substantially increase the face widths of the gears, thereby increasing torque capacity.

The improvements made to the synchronizer were much more than a simple trimming of fat. The T-56 used a hoop-style retainer to hold three stamped-steel keys in place, attempting to put equal pressure at three points of a circle. Although it worked reasonably well, the design was prone to uncontrolled movement that in extreme cases could allow the keys to dislodge.

Though narrower in design, the blocker and friction rings in the TREMEC TR-6060 and Magnum have an increased diameter and a standard triple-cone arrangement for substantially more surface area and strength than the double-cone setup found in the majority of T-56s. In the case of the TR-6060, the friction materials themselves vary by application. Here, the material shown is sintered bronze. The T-56 also used several different materials. The T-56 ring shown here is a ‘particlized’ carbon. All TR-6060 and Magnums feature triple-cone baskets in the 1-2 position, and double-cone arrangements throughout the rest of the box, including Reverse. The T-56, conversely, offered a mix of double and triple cones, depending on the application, for First and Second, and, in many cases, a single cone for all other gears.

T56 Gearbox Replacement

A common complaint from those who liked to abuse their T-56 was the unit’s propensity to bend aluminum shift forks; thus, the installation of steel forks was a common upgrade. The problem was not so much with bending the fork prongs, but rather an issue found at the shift-rail bore. A keyway cut into the bore for placement of the shift plates, or z-links, had a tendency to wallow out and allow the fork to deflect on the rail, opening the door to a host of secondary shift-related issues. In the TR-6060 and Magnum, these links have been cast into the fork, eliminating the concern and allowing the forks to be both light and strong.

The most notable difference between the input shaft used in the T-56 and the TR-6060 and Magnum is the bearing hardware, which is much larger in the TR-6060 and Magnum. This helps the transmission endure significantly increased torque. In addition, all Magnums (and most TR-6060s) use a 26-spline input shaft for maximum surface area and subsequent strength.

Perhaps the greatest difference between the Magnum and all other OE units (TR-6060s included) is its wide range of flexibility features with the explicit intent of being more swap-friendly. Other Magnum components include dual (electronic and mechanical) speedometer pickups, dual-pattern crossmember mount area and commonized 31-spline output shaft that trumps the toughest T-56 in strength.

There’s still a lot of ground we could cover, and perhaps we will in a future story, but hopefully you now (if you didn’t before) understand and appreciate some of the critical differences between the T-56 and its replacement, the Magnum. Although the T-56 was a great transmission, and continues to faithfully serve in many heavy-hitting street cars, it is simply no match for the Magnum transmission that it ultimately inspired.